Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy (hydrostatic energy i.e. flow, pressure). It generates flow with enough power to overcome pressure induced by the load at the pump outlet. When a hydraulic pump operates, it creates a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line to the pump and by mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system.

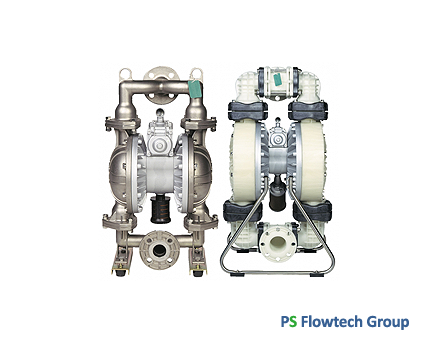

Air Operated Double Diaphragm pumps Plastic

Air Operated Double Diaphragm pumps from YAMADA with durable, modern construction for multiple use. The experience of its producer YAMADA is making of them one of the world wide market leaders. During the pump developmet YAMADA even decreased the number of parts from which it made. Therefore it is no more science-fiction to minimize the stock value of parts for the endusers. YAMADA was not looking back, they followed vissions and future without compromises.

-

Max. flow (l/min): 820

-

Max. discharge head (bar): 8

-

Max. suction depth (m): 8

-

Max. pumped liquid temperature (°C): 110

-

Materials available: SS316L, SS316, Cast Iron, Aluminium, PE 1000, PTFE, Aluminium with PTFE coating

-

Realized applications: oils, solvents, cooling liquids, lubricants, paints, latex, pigments, ceramic mass, ceramic sludge, paste, glaze, acids, hydroxides, TiO2, aditives, sirup, chocolate, honey, marmelade, milk, cottage cheese, cream, ketchup, mayonaise, mustard, juice, pupls, concentrates, colorings, and many others...

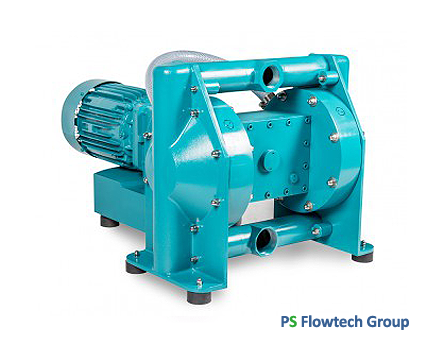

Electrically driven Double Diaphragm pumps

Electrically driven double diaphragm pumps from DELLMECO are offering you confortable saving of running cost with keeping all the advantages of a air operated pumps. With this product range DELLMECO became to be a trend-setter in the pumping-world.

-

Max. flow (l/min): 820

-

Max. discharge head (bar): 8

-

Max. suction depth (m): 8

-

Max. pumped liquid temperature (°C): 110

-

Material execution: SS316L, SS316, Cast Iron, Alluminium, PE, PTFE, Alluminium with PTFE coating

-

Realized applications: oils, solvents, cooling liquids, lubricants, paints, latex, pigments, ceramic mass, ceramic sludge, paste, glaze, acids, hydroxides, TiO2, aditives, sirup, chocolate, honey, marmelade, milk, cottage cheese, cream, ketchup, mayonaise, mustard, juice, pupls, concentrates, colorings, and many others...

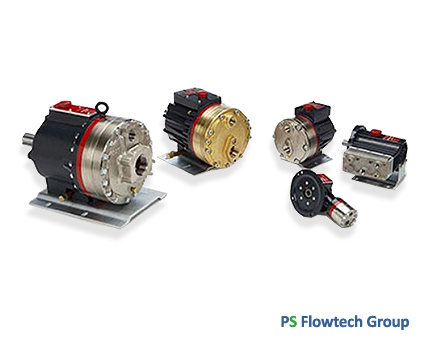

Positive displacement Seal-less pumps

Hydra-Cell positive displacement diaphragm pumps feature a seal-less pumping chamber so there are no seals, packing or cups to leak or replace. The seal-less design and check valves enable Hydra-Cell to handle abrasives and particulates that would damage other types of pumps.

In addition, Hydra-Cell can run dry indefinitely without damage to the pump.

The multiple-diaphragm design of Hydra-Cell provides virtually pulse-less, linear flow without the need for expensive pulsation dampeners.

-

Max. flow (l/min): 248

-

Max. discharge head (bar): 172

-

Max. pumped liquid temperature (°C): 121 (for metallic head), 60 (for non-mettalic head)

-

Materials available: metallic, PP, PVDF, Brass

-

Realized applications: chemicals, solvents, acids, hydrocarbons, natural gas liquids, alkalis, polymers, aqueous ammonia, resins, slurries, wettable powders, shear sensitive liquids, recycled or dirty liquids...

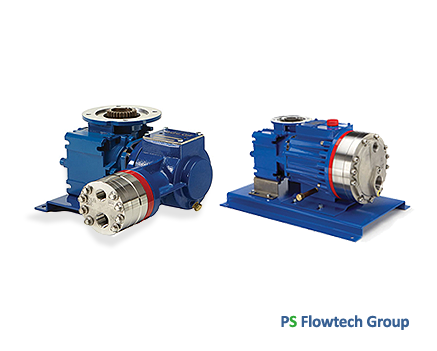

High Horsepower Triplex / Quintuplex Pumps

T and Q Series pumps feature the Hydra-Cell seal-less design, eliminating cleanup costs from leaking seals or packing and protecting operators from dangerous fluids such as those containing hydrogen sulphide.

-

Max. flow (l/min): 595

-

Max. discharge head (bar): up to 345

-

Max. pumped liquid temperature (°C): 82 (for metallic head)

-

Materials available: nickel Aluminum Bronze (NAB), Duplex Alloy 2205, 316 stainless Steel, Hastelloy CX2M

-

Realized applications: machine tool coolant filtration, lawn care, propellant packaging, power generation turbine emissions, parts washing, reverse osmosis, agricultural spraying, car wash systems

Metering pumps

Hydra-Cell metering and dosing pumps provide a reliable and cost effective alternative to traditional metering and dosing pumps.

Like them, Hydra-Cell metering and dosing pumps use hydraulically balanced diaphragms, but Hydra-Cell’s unique design with multiple diaphragms in a single pump head provides significant advantages.

-

Max. flow (l/h): 2 808

-

Max. discharge head (bar): 172 (for metallic head), 24 (for non-metallic head)

-

Max. pumped liquid temperature (°C): 121 (for metallic head), 60 (for non-metallic head)

-

Materials available: Brass, Cast Iron, Hastelloy C, PVDF, Polypropylene, 316L Stainless Steel

-

Realized applications: chemical metering & injection, food & beverage, processing, high-pressure chemical reaction, chromatography, oil &gas (offshore and onshore), personal care, product manufacturing, plastics processing, polyurethane foam production, power plant/boiler feed, water & wastewater treatment

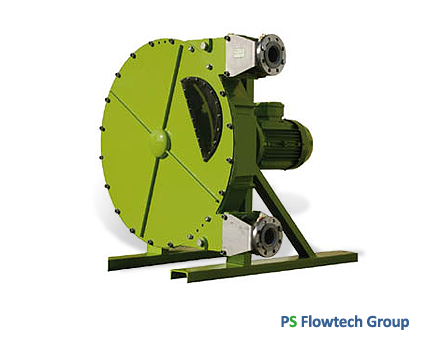

Hose pumps and Peristaltic pumps

Hose pumps from our production are made from robust Nodular Cast Iron parts. Together with the heavy duty hoses with multiple reinforcement makes this pump undestroyable. Its used for most critical abrasive applications where other types of pumps fails within days. This construction enables fantastic self-priming ability and high discharge head up to 16 bar. Optimal for the use of filling filterpresses. The Peristaltic range "Low pressure" is used for exact dosing up to 3 bar in chemical segment, cosmetics or food.

-

Max. flow (m3/h): 150

-

Max. discharge head (bar): 15

-

Max. suction depth (m): 9,8

-

Max. pumped fluid tempetarure (°C): 135

-

Materials of hose: NR, NBR, EPDM, CSM

-

Realized applications: Kieselguhr, active carbon, SIC suspension, yeasts, ketchup, pulps, paste, oils, aditives, sludges, concrete, kaolin and others....

Rotary lobe pump - Lined

Lobe pumps with rubber lining is outstanding solution fo handing all dirty liquids and suspensions where the non.lined execution is too sensitive to provide the job with long lifetime and reliability.

-

Max. flow (m3/h): 300

-

Max. discharge head (bar): 5

-

Max. pumped liquid temperature (°C): 90

-

Realized applications: sludges, waste water, agriculture, fish production, mining, petrochemical segment

-

Certificates: RoHS, GOST, EHEDG, 3A, FDA

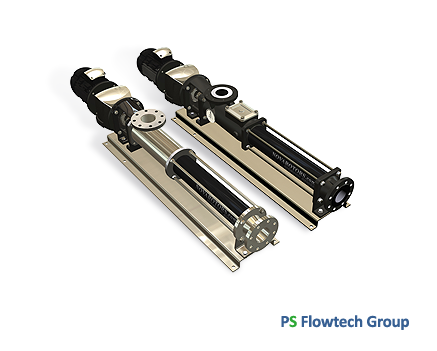

Progressive Cavity pumps

The progresive cavity pumps from the middle size family owned manufacturer focussed onto making quality products without compromises. Its design inspired by the market leaders such as Seepex and Netzsch is guarantie is long lifetime and minized running costs.

-

Max. flow (m3/h): 400

-

Max. discharge head (bar): 48

-

Max. pumped liquid temperature (°C): 120

-

Materials of wetted parts: Cast Iron, SS304, SS316L, (Stators: NR, NBR, EPDM, Hypalon)

-

Realized applications: filterpress filling, glues, oils, paints, bentonit, easte water, sludge, mud, various suspensions...

-

Certificates: FDA, ATEX, GOST, RoHS

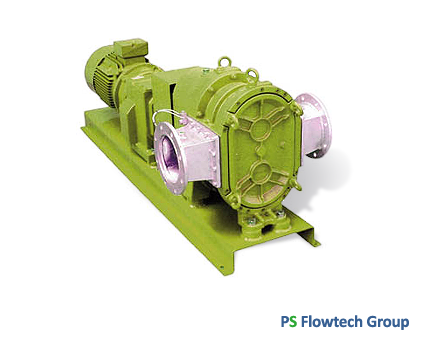

Rotary piston pumps (Lobe/Wing)

Lobe pumps and piston pumps, named also together as Rotary piston pumps with robust design of shafts and flat front cover for durability and perfect cleanability. Thanks to its precise sanitary desing it is very much used in food, cosmetics or pharmaceutical applications, everywhere where universal pumping solution for thick or shear sensitive liquids is needed.

-

Max. flow (m3/h): 100

-

Max. discharge head (bar): 20

-

Max. pumped liquid temperature (°C): 150

-

Material of wetted parts: SS 316, SS 316L

-

Certifications: RoHS, GOST, EHEDG, 3A, FDA

Gear pumps - Internal

Internal process gear pumps for difficult applications from the "Hardline Quality" sets on the market new standards, when high quality and robust construction not always means High-End price.

-

Max. flow (m3/h): 390

-

Max. discharge head (bar): 14

-

Max. pumped liquid temperature (°C): 350

-

Max. viscosity (cSt): 450 000

-

Materials of wetted parts: Cast Iron, Nodular Cast Iron, Steel, SS 316

-

Realized applications: asfalt, oils, adhesives, kaolin, glues, paint, chocolate

-

Certificates: RoHS, GOST

Gear pumps - External

External process gear pumps for difficult applications from the "Hardline Quality" sets on the market new standards, when high quality and robust construction not always means High-End price.

-

Max. flow (m3/h): 50

-

Max. discharge head (m): 30

-

Max. pumped liquid temperature (°C): 250

-

Max. fluid viscosity (cSt): 450 000

-

Material execution: Cast Iron, Nodular Cast Iron, Steel, SS 316

-

Certificates: RoHS, GOST

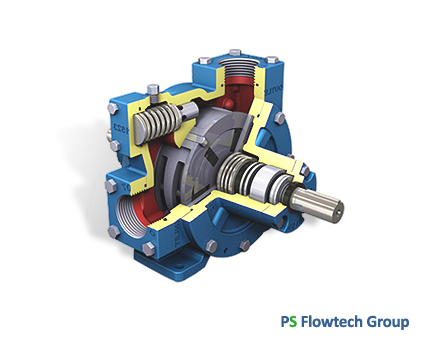

Vane-Pumps

LPG pump type "Vane pump" used for unloading of LPG, butane, propane, freons, DME, ammonia and other low-viscosity liquids.

-

Max. flow (m3/h): 365

-

Max. discharge head (bar): 8,5

-

Max. pumped liquid temperature (°C): 150

-

Max. fluid viscosity (cSt): 100

-

Material of wetted parts: Cast Iron, Nodular Cast Iron, Steel, SS 316

-

Certification: ATEX, RoHS, GOST