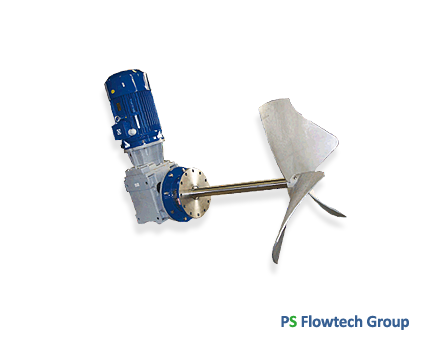

Mixer AV - Top Entry

AVF with worm gearbox. Mainly used on closed tank up to about 15 m3, With different kind of seals AV, AVF, AVF, AVS, AVSH, AVC, ECO.

-

Vertical installation for low up to high viscosities

-

Top entry vertical instalation

-

instalation of number of impellers on one shaft

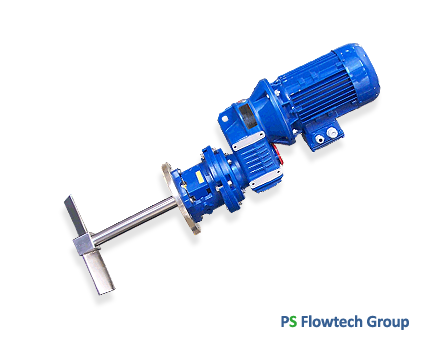

Mixer AL - Side Entry

High speed mixer, economicaly most optimal solution for tank with low viscosity medium.

-

side entry installation

-

high speed for low viscosities, Tank volume: 100 - 1400 m3

-

seal: mechanical, in contact with fluid

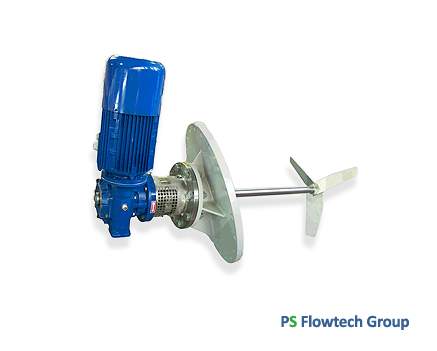

Mixer ALS - Side Entry

Low speed ALS mixer for liquids with higher viscosity 600 up to 6000 m3/h . Range ALC is available in more alternatives of seal design for better servicing.

-

aplication into wall of tank, or from the bottom

-

low speed for low viscosities

-

tank volume: 600 - 6000 m3

-

seal: mechanical, in contact with mediium or outside of medium

Mixery ALF - Side Entry

Mounted into wall of tank, or from the bottom. Used for easy applications, for tanks up to 17m hight. Vhodné pro jednodušší aplikace, do vyšších tanků až 17m vysoké. Worm gearbox has more advantages such us low price, weight and smaller size. Mixer shaft is directly fixed into gearbox hollow shaft and fixed by screw. so there is no need to used intermediate coupling.

-

Typ W - sugar production

-

Typ E - for clean liquids, against settlement of particles

-

Typ X - for ATEX certified application

-

Typ S - with DIN lantern and build in lipseal, single mechanical seal, double mechanical seal.

Static mixers

Static mixers are among those impliest and cheapest solutions for homogenizing media and dosing of additives. Our products are technologically among the best on the market, using a production process, from design to copy the currently best technology. Performance is dependent on the ratio and flow rate, viscosity and density of the liquids to be mixed. On the basis of these data and experience in many sectors GREC can always choose the right type and configuration of the static mixer.

There is ATEX available in Zones 1 and 2, D-dust, G-gas. If it can supply mixers complying with European standards for pressure vessels (PED). Standard execution AISI 304, AISI 316L or plastic PP / PVC. The main applications are in the field of water treatment, production of paints and varnishes, or in reducing the emissions of smoke.